Engineering

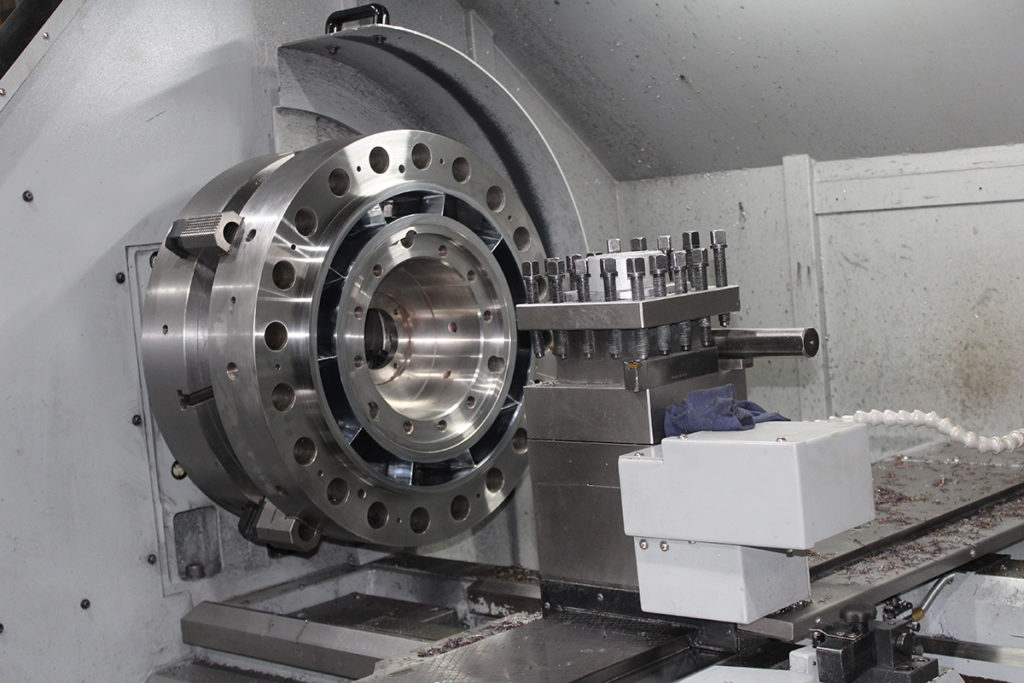

CNC Engineering

Modern CNC engineering is a speciality that is found within the field of mechanical and precision engineering. It accounts for the production of a hugely wide and varied range of parts for hundreds of different industries. Our modern CNC lathes and milling machines can mass produce parts to a very high level of precision.

See our YouTube Channel for some videos: BCH Services Kent Ltd – YouTube

Extrusion and Injection Tooling

B.CH Services currently holds several contracts for major manufactures of moulded piping offering a dressing service to exacting standards or re-manufactured components to suit your requirements. We use materials such as P20 and 1.2316 stainless steels to manufacture the majority of our tools.

Die and mould repairs are carried out in house on our cutting edge CNC machines. We can handle up to 3 tons in weight and 1.5 meters in diameter for extrusion dies and mandrels.

Our largest CNC milling machines are able to handle large dies for repairs and modifications with 1.5 meters travel in the X axis and over 600mm in the Y axis we can machine most dies.

We have a long standing relationships with hard plate chroming companies to ensure quality from start to finish.

Welding & Fabrication

We offer a vast amount of experience and expertise when it comes to welding and fabrication, catering for most types of welding requirements and fabrication needs. We offer a line Boring Service along with Mig, Tig and Arc welding of Mild and Stainless Steel along with Aluminium welding services .

We can offer on site in situ engineering by means of Rotary Welding and Line Boring. This machine works by Rotary Welding a worn hole and machining it back to its original size. We can then push fit any bush with our powerful 60 ton hollow jacks.

This process is easily adapted to a multitude of industries and sectors. Please contact us to discuss our services.

Tool Makers

Our tool makers are a class of machinists in the manufacturing industry who make jigs, fixtures, dies, moulds, cutting tools, gauges, and other tools used in manufacturing processes to the highest possible standards. We are able to offer customers a full service from tool design all the way through to manufacture and installation. We are also able to offer repairs, overhaul and modifications to any die and mould you may require. Please contact us for further assistance.

Our Machinery

We have a comprehensive line up of machinery including a number of CNC Lathes, CNC Milling Machines and Vertical Radial Drill. Needless to say, as far as our machining capabilities we are unrivalled. Here is a list of the machinery currently in use here at B.CH Services:

Lathes

XYZ CNC XL780 X 3M

Turning length 3000mm

Sawing over the bed 780mm

Spindle bore 160mm

Chuck size 650mm

Swing in the gap 1020mm

XYZ CNC SLX425 X 2M

Turning length 2000mm

Sawing over the bed 425mm

Spindle bore 80mm

Chuck size 250mm

Swing in the gap 680mm

Toss SN65 Manual Lathe

Turning length 4000mm

Sawing over the bed 550mm

Spindle bore 78mm

Chuck size 350mm

Swing in the gap 680mm

Swift Manual Lathe

Turning length 1500mm

Sawing over the bed 1035mm

Spindle bore 100mm

Chuck size 750mm

Swing in the gap 1050mm

Milling Machines

XYZ CNC SMX5000

X TRAVEL 1524mm

Y TRAVEL 596mm

Z TRAVEL 584mm

XYZ CNC 4000

X TRAVEL 1016mm

Y TRAVEL 596mm

Z TRAVEL 584mm

Grinders

Jacobson surface grinder

Mag chuck 1000mm x 300mm

Astra surface grinder

Mag chuck 300mm x 150mm

Radial Drill

Mas 2.2m Radial Arm Drill

2200mm radial arm

Max drilling Hight 1800mmg

If you have any questions please get

in touch with us:se contact us to bencheeseman@bchservices.co.uk

01227 721040 / 07825 837008

We live and breathe Engineering

& Repairs!

ISO 9001 Certified